01 Nov 2024

Clean and prolong the life of reusable labware, while eliminating residues

Laboratory procedures can be compromised by interfering residues that prevent reliable results. At the same time, labware and instrumentation budgets are wasted by cleaners that etch, cloud or damage labware surfaces. Alconox detergents remove interfering residues without causing equipment deterioration - even when handling tough proteinaceous soils or radioisotope decontamination.

Formulated for all lab cleaning applications, Alconox products work effectively and economically without the hazards of strong acids and solvents, and they are free rinsing, corrosion inhibiting and biodegradable.

Alconox cleaners handle everything from lab glassware to ceramics and metal

The practical, safe choice for cleaning field sampling equipment without cross-contamination

Accurate environmental testing of ground or surface water, soil or sediment requires the use of clean instruments, free of cross-contamination. From delicate pH meter probes to bailers, split-spoon samplers, augers, dredges and flow-through cells, each requires the appropriate process and detergent. Alconox aqueous detergents help maintain the level of testing accuracy required by EPA guidelines - without the risks and hazards associated with solvents. The following equipment is subject to laboratory detergent cleaning guidelines:

United States EPA Environmental Services Division standard cleaning procedures require a “phosphate-free laboratory detergent such as LIQUINOX” for Teflon®, glass and stainless steel equipment used to sample trace organic compounds or metals.

Alconox environmental cleaning products for field and lab applications:

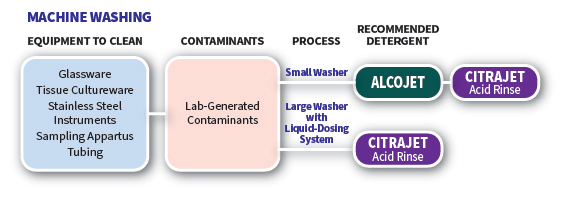

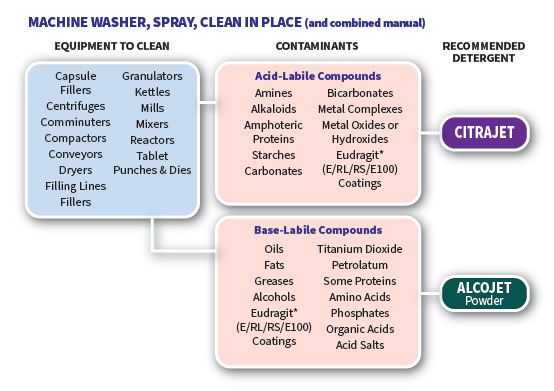

Handle tough critical cleaning jobs, from tablet presses to mixing tanks

If you have pharmaceutical or biotechnology production machinery that must be clean and free of interfering residues, Alconox has an acidic, neutral or alkaline biodegradable detergent for the job, including meeting applicable disposal requirements. Whether your process is manual, immersion or circulate CIP, almost any glass, plastic, metal, rubber or porcelain surface can be safely, effectively and economically cleaned with an Alconox detergent.

Alconox detergents are available worldwide with consistent formulations, certificates of analysis, ingredient toxicity data, shelf life information, residue sampling techniques, ingredients disclosure, analytical methods, lot number tracking, and validation support.

Maintain sanitary processing conditions in accordance with stringent guidelines

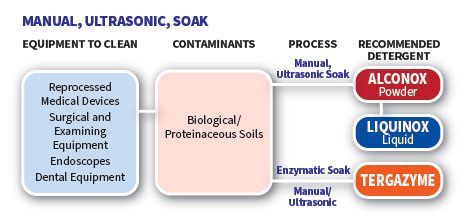

Meet the most demanding criteria for effective cleaning of reusable instruments and equipment prior to sterilization

| INDUSTRY/APPLICATION KEY CONCERNS | ARTICLES CLEANED/SOIL REMOVED | CLEANING METHOD | POWDER | LIQUID |

|---|---|---|---|---|

| Healthcare/Veterinary

Effective preparation for sterilization, longer instrument life. Reduce waste. | Surgical, anesthetic, and examining instruments and equipment. Catheters and tubes. | Manual, Ultrasonic, Soak | ALCONOX | LIQUINOX |

| Machine washer, sani-sterilizer | ALCOJET | |||

| Blood, body fluids, tissue on instruments. | Manual, Ultrasonic, Soak | TERGAZYME | ||

| Pharmaceutical/Medical Device/ Biotechnology

Passing cleaning validation for FDA good manufacturing practices. For stainless steel, glass, plastic, elastomer cleaning. | Titanium dioxide, petrolatum, oils, emulsions, ointments, carbopols, lacquers, zinc oxides, proteins, steroids, alcohols, sugars, and Eudragit* (L/S/L30/D55/NE30D) polymers. | Manual, Ultrasonic, Soak | ALCONOX | LIQUINOX |

| Machine washer, power wash, CIP | ALCOJET TERGAJET (p-free) | |||

| Inorganic residues, salts, metallics, pigments. Eudragit* (E/RL/RS/E100) polymers, amphoterics, coatings, amines, ethers, starches, alkaloids. | Manual, Ultrasonic, Soak | CITRANOX | ||

| Machine washer, power wash, CIP | CITRAJET | |||

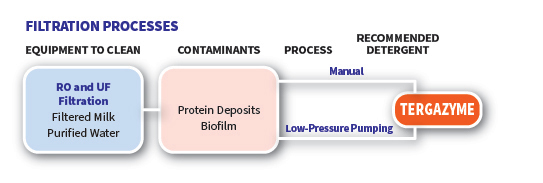

| Protein/ferment residues. R/O, U/F membranes. | Manual, Ultrasonic, Soak | TERGAZYME | ||

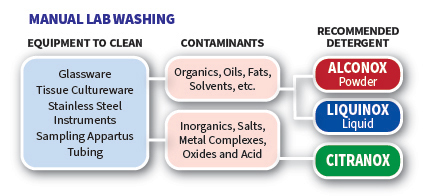

| Laboratory/Environmental

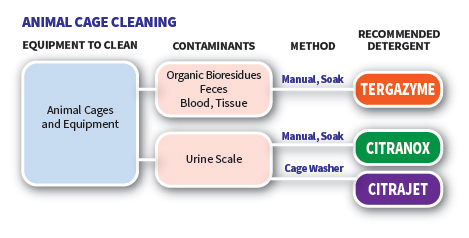

Reproducible results, no interfering residues, extending equipment life. Keep laboratory accreditation. Laboratory safety. | Glass, metal, plastic labware, ceramics, tissue culture, porcelain, clean rooms, animal cages, bioreactors, tubing, benches, safety equipment. | Manual, Ultrasonic, Soak | ALCONOX | LIQUINOX (p-free) |

| Machine, power spray, labware washer, washer-sterilizer, cage-washers | ALCOJET TERGAJET (p-free) | |||

| Tubes, reusable pipets. | Siphon-type washer-rinsers | ALCOTABS (tablet) | ||

| Microbiology, water lab, and environmental sampling. Phosphate-sensitive labware. EPA procedures. (Acid for water rinse cycle.) | Field, Manual, Ultrasonic, Soak | TERGAJET | LIQUINOX | |

| Machine washer, labware washer | TERGAJET | CITRAJET-acid | ||

| Radioactive equipment/contaminants. Stopcock grease. | Manual, Ultrasonic, Soak | ALCONOX | LIQUINOX | |

| Machine washer, warewasher | ALCOJET | |||

| Trace metals, metal oxides, scale, salts, starches, amines. | Manual, Ultrasonic, Soak | CITRANOX | ||

| Machine washer, warewasher | CITRAJET | |||

| Proteinaceous soils, bio-wastes, tissue, blood and other body fluids, fermentation residues. | Manual, Ultrasonic, Soak | TERGAZYME | ||

| Glassware washer | ALCOJET | |||

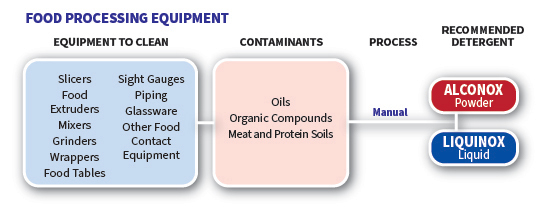

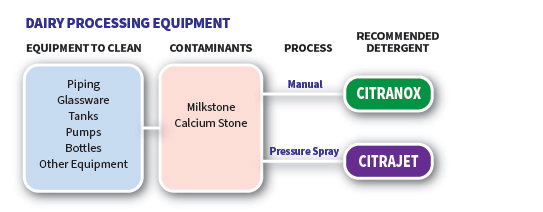

| Foodservice & Food Manufacturing

Avoid interfering residues on food-contact equipment and effectively remove soils commonly found in food operations. For complete foodservice detergent selection guide, visit AlconoxFoodservice.com . | Stainless steel, glass, and food production equipment. | Manual, Ultrasonic, Soak | ALCONOX | LIQUINOX |

| Machine wash, pressure wash, CIP | ALCOJET | |||

| Oxides, scale, trace metals, salts, milkstone and corrosion. | Manual, Ultrasonic, Soak | CITRANOX | ||

| Machine wash, pressure wash, CIP | CITRAJET | |||

| Filter membranes, proteins, biofouling. | Manual, Ultrasonic, Soak | TERGAZYME |

| Product | Form | Foam | Dilution (%) | Amount (gm/L or mL/L) | Min Wash Temp. | Usual Wash Temp. | Max Wash Temp. |

|---|---|---|---|---|---|---|---|

| ALCONOX | Powder | Yes | 1 | 10 | Ambient | Warm | Boiling |

| TERGAZYME | Powder | Yes | 1 | 10 | Ambient | 43 - 49°C | 54°C |

| LIQUINOX | Liquid | Yes | 1 | 10 | Ambient | Warm | Boiling |

| CITRANOX | Liquid | Yes | 1 - 2 | 10 - 20 | Ambient | Hot | Boiling |

| ALCOJET | Powder | No | 1/2 - 1 | 5 - 10 | Warm | Hot | Boiling |

| ALCOTABS | Tablet | Yes | Ambient | Ambient | Boiling | ||

| LUMINOX | Liquid | No | 2 - 5 | 20 - 50 | Ambient | Warm | Boiling |

| CITRAJET | Liquid | No | 1 - 2 | 10 - 20 | Ambient | Hot | Boiling |

| TERGAJET | Powder | No | 1/2 - 1 | 5 - 10 | Warm | Hot | Boiling |

| DETONOX | Liquid | Yes | 1 - 3 | 10 - 30 | Ambient | Warm | Boiling |

Directions: Dilute detergent (see chart) using warm (about 50°C) or hot (about 60°C) water. Ambient temperature water may be acceptable, especially for pre-soak. For difficult soils, use very hot water (above 65°C) and double the recommended amount of detergent. When cleaning solution may be reused, make up fresh solutions frequently as needed.

Typical Use: To clean small items - hospital catheters and tubes, small metal parts - and large tank interiors, including pharmaceutical and other blending tanks.

An excellent pretreatment method for loosening soils and preventing drying prior to further cleaning - especially for labware or medical instruments.

Advantages: Very little physical effort or expense.

Concerns: Extremely dirty articles or difficult soils may require further cleaning.

Directions: Soak, completely submerged in solution, until clean. This may take several hours, depending on the type of soil. Remove and rinse thoroughly.

Typical Use: To clean multiple batches of articles or for fast, convenient cleaning.

Advantages: Fast, effective, reproducible, penetrating cleaning.

Concerns: Capital cost, material tolerance for ultrasonic agitation.

Directions:

Make up detergent solution in a separate container.

Add detergent, run machine 10 minutes to degas, allow heater to heat.

Place groups of small articles in racks or baskets.

Align irregularly shaped articles so the long axis of any part faces the ultrasonic transducer (usually the bottom).

Immerse articles to be cleaned for 2 - 10 minutes, or longer, as needed. Remove and rinse thoroughly.

Orient or rotate parts to release air from blind holes

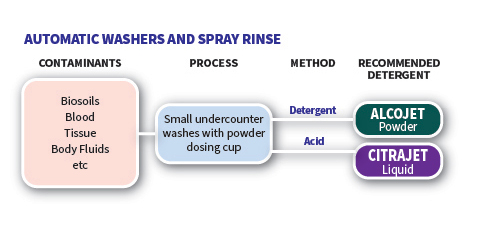

Typical Use: For high-volume cleaning using washer-sanitizers, warewashers, conveyor-washers, or spray and pressure washers.

Advantages: Fast, effective, high volume cleaning.

Concerns: Capital cost; article’s ability to withstand machine washing conditions.

Directions: Load articles into racks so that open ends face toward spray nozzles. Place difficult-to-clean articles with narrow necks and openings near the center of the rack, open-side down, preferably on special racks with spray nozzles pointing directly into them. Minimize touching between articles.

Minimize fluid trapping orientation of parts - optimize drainage.

Group small articles in baskets to prevent dislodging by spray action.

Use only low foaming detergent as per machine manufacturer dose instructions. If no instructions, use a 1% solution of wash water. Use more or less as needed.

Use hot water (above 60°C).

Use CITRAJET as an acid rinse and neutralizer where desired.

Most machines have at least three rinse cycles. Refer to machine manufacturer’s directions.

This acronym is formed from the first letter in each of the nine critical variables in cleaning. And each offers opportunities for cleaning process optimization.

Before cleaning - Presoak, prevent residues from drying and hardening, or stop any pre-cleaning procedures that make cleaning more difficult.

Agitation - The more agitation, the better. Add or increase scrubbing, ultrasonic, spraying or flowing.

Time - The longer the cleaning, the more available cleaning capacity is used. Until you run out.

Heat - Every 10°C increase in cleaning temperature, doubles the cleaning speed. Clean as hot as practical,

without damaging your substrate.

Orientation - Surfaces must be oriented to contact cleaning solution and rinse water. Also, rotate parts to release air in

blind holes, and rack to prevent holding liquid between surfaces.

Chemistry - Use detergent suitable for the type of residue (acid or alkaline) and cleaning method (low foam for high agitation; high foam for immersion and ultrasonic).

After cleaning - Avoid recontamination and corrosion causing humidity and heat.

Rinse - Use suitably pure rinse water to avoid rinsewater residues. Hot rinse avoids breaking emulsion and redepositing. Cold rinse reduces corrosion.

Dry - Removing water by alcohol dip, wiping, blowing or centrifuge reduces rinse-water residues and corrosion.

(See following section for more information.)

Corrosion during cleaning is accelerated by the same things that accelerate cleaning: heat, aggressive chemicals, time, and agitation. To reduce metal corrosion, in approximate order of effect, use less heat, corrosion inhibited detergents, lower pH or pH appropriate detergents, shorter cleaning time, and less agitation. Avoid mixed metals in the same bath that form batteries and deposit galvanic oxides. The following techniques may work to limit corrosion, based on the material and/or process involved:

• Metal: Use the mildest pH detergent and avoid mixed metals in the same bath.

• Aluminium: After abrasion exposes pure metal surface, allow air passivation time prior to cleaning. Use mild acid

cleaners such as CITRANOX or CITRAJET to avoid alkaline attack.

• Plastic: Use less aggressive cleaners, containing less solvent or surfactant character. Or use lower concentrations of those cleaners, lower cleaning temperatures, less contact time, and less agitation. For stressed polycarbonate and acrylic use surfactant-free DETOJET for cleaning. Unstressed material is not a concern. Avoid alkaline cleaners on polyurethane.

• Mild sensitive steel: Avoid “flash rusting” by rinsing with cold water and using rapid water-removing drying techniques such as dipping in isopropyl alcohol to form an evaporating azeotrope that removes water safely, centrifuge dry, wipe dry, air knives, and drying with oxygen-free gas such as dry nitrogen. Or add a suitable corrosion inhibitor to the rinse water, as long as you can tolerate corrosion-inhibitor residues. Do not use evaporative drying such as air drying or oven drying.

• Sensitive steel: Clean with an inhibited cleaner and isopropyl alcohol rinse (or add a corrosion inhibitor to the rinse water).

• Galvanic corrosion: Avoid mixed metals in the same bath that can form a battery and deposit oxides on one of the metals. For example, many metals will plate out their oxides on aluminum if the two metals are cleaned in the same bath. Intact stainless steel is generally OK as a mixed metal, but iron, steel, brass, aluminum, bronze and other metals can be a problem mixed with other metals.

For the highest levels of critical cleaning, especially to avoid cross contamination, only freshly prepared solutions should be used. For industrial cleaning applications, however, bath life can be extended while still achieving high levels of cleaning.

Bath life extension techniques:

• Filtering particulates

• Cooling and settling of sludge

• Cooling and skimming oils

• Adding half again as much detergent as the initial load after partially depleting the cleaning life of a bath

Conductivity, pH and % solids by refractometer can be used to measure bath detergent concentration. In general, a pH change of 1 unit toward neutral indicates an exhausted cleaning solution. Under frequent daily use, detergent solutions can rarely be used more than a week, even when being extended.

Free-alkalinity titration can be used to extend bath life where the soils deplete free alkalinity, as follows:

• Titrate a fresh solution to determine free alkalinity

• Titrate the used solution to determine the percent drop in free alkalinity

• Add detergent to the used bath to bring the free alkalinity back to the new-solution level

For example if your initial solution contains 100mL of cleaner concentrate and there is a 25% drop in free alkalinity, try adding 25mL of cleaner concentrate to recharge the solution. Perform a new free-alkalinity titration the first few times to confirm that the detergent is linear with respect to free free-alkalinity depletion. This bath life extension cannot be repeated indefinitely: sludge will eventually form, requiring a fresh solution.

We have chosen not to feature any of the Alconox range which are dangerous goods as we do not stock and freight is expensive.

If required - please enquire.

| Heavy-duty alkaline degreaser. Nonionic liquid for labware and machine washers, manual and ultrasonic cleaning. Corrosion-inhibited for glass, metals and plastic. No interfering residues. Has inhibitory residue test. USDA/FDA compliant. Dilute 1:200. pH 12 |

| Nonionic liquid for machine, spray-CIP, manual, soak and ultrasonic cleaning. High emulsifying and penetrating formula. Corrosion-inhibited for glass, metals and plastic. No interfering residues. Has inhibitory residue test. FDA compliant. Dilute 1:200. pH 12 |

| Nonionic detergent for PC board washing machines, manual and ultrasonic cleaning. Ion and chelate free for no conductive residues on electronics and no chelate interference in waste. Phosphate-free. Dilute 3:100. pH 11 |